Turbocharging has revolutionized modern engines, helping automakers create vehicles with astonishing power, efficiency, and performance. As automotive technology has advanced, turbochargers have evolved, using new materials, designs, and control systems to make them more fuel-efficient and less polluting without sacrificing power.

Turbochargers were created to improve the performance of large engines. They have since become standard equipment in many different types of cars, including small cars, hybrids, and electric cars. In today’s tough market, understanding the latest developments in turbocharging technology can help you understand how the automotive industry is improving performance and reducing its impact on the environment.

How a Turbocharger Works and Its Uses?

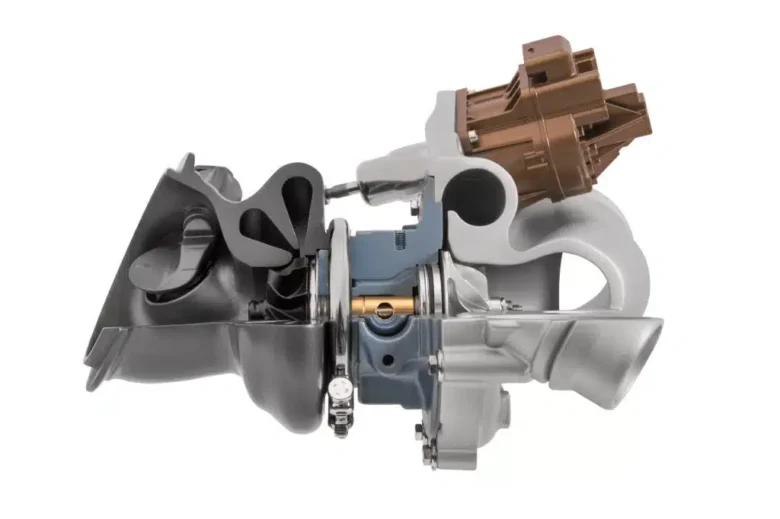

A turbocharger forces more air into the engine’s combustion chamber, making it more powerful. This process makes the internal combustion engine more efficient because it adds more air, allowing more fuel to be burned and producing more power without making the engine larger. Naturally aspirated engines derive their power from air intake alone. A turbocharger, on the other hand, compresses air and feeds it into the engine, creating a denser mixture that produces more power.

Turbochargers have long been used in high-performance cars and racing cars. Today, they are also used in many other vehicles to meet consumer demand for fuel-efficient and environmentally friendly vehicles. As fuel economy standards continue to improve, turbochargers have become a more important part of everyday automotive technology.

The Rise of Electric Turbochargers and Their Benefits:

The birth of electric turbochargers is one of the most significant developments in modern turbocharger technology. A conventional turbocharger draws its power from exhaust gases. Electric turbochargers, on the other hand, use an electric motor to spin a rotor, so they respond immediately instead of over time like traditional turbochargers. This design provides better throttle control and lower fuel consumption, especially at low engine speeds.

This makes them ideal for city driving which involves a lot of stop-and-go driving. An electric turbocharger also gives you more control over the boost pressure applied to your engine, allowing you to fine-tune performance. This new development is a major step towards electrification in the turbocharging sector and follows the larger trend towards electric and hybrid vehicles.

Variable Geometry Turbocharger for Better Performance:

Variable geometry turbochargers (VGTs) are becoming increasingly popular because they can vary the amount of exhaust gases flowing into the turbine, improving performance across a wide range of engine speeds. The turbine blades in a conventional turbocharger are fixed, meaning they work best within a certain engine speed range. VGTs, on the other hand, have blades in the turbine that can be moved at different angles. This changes the size of the air path.

This design allows the turbocharger to perform optimally at both low and high engine speeds. This increases overall efficiency and reduces the problem of “turbo lag” that occurs with conventional turbochargers. That’s why VGT is the first choice for high-performance and fuel-efficient cars. They offer a good mix of electric power and gasoline consumption.

How Do New Materials Affect Turbocharger Lifespan?

Today’s turbochargers are made of high-tech materials that can withstand high temperatures and pressures. The exhaust gases used to power turbochargers make them very hot, which shortens their lifespan. To solve this problem, companies are starting to use materials such as titanium, ceramics, and advanced metals that are more durable and don’t melt when heated. For example, titanium is very light and very strong, which makes turbochargers work better and last longer.

Many people also prefer ceramic parts because they don’t break when heated. These materials not only make turbochargers last longer, but they also make them more powerful because they can operate safely at higher pressures and speeds. One of the most important factors that are currently improving turbine technology is the shift to high-performance materials.

Two-Stage Turbocharging for Higher Efficiency:

Another new technology designed to make engines run better and use less fuel is two-stage turbocharging. This setup uses two different-sized turbochargers. Each turbine operates at a different engine speed. A smaller turbocharger allows the car to accelerate quickly at low speeds. At higher speeds, a larger turbocharger takes over to deliver more power. The engine doesn’t have to rely so heavily on a single turbocharger, which allows power to flow more smoothly and efficiently.

Diesel engines are better off with two-stage turbocharging because they require a lot of low-end and top-end power. Optimizing power delivery across different speed ranges is a one-way, two-stage turbocharging that helps improve performance and fuel economy. That’s why it’s becoming increasingly popular in personal and commercial vehicles.

Turbocharger and Wastegate Technology Check:

Wastegate valves are a crucial component of a modern turbocharger system because they aid in regulating boost pressure and guard against engine damage from excessive power. When the boost pressure reaches a certain level, the wastegate valve allows exhaust gases to bypass the turbocharger. This keeps your engine running optimally and protects it. The technology behind modern wastegates has come a long way.

An electric unit now replaces the old mechanical unit. With an electronic wastegate, you can control boost levels more precisely, resulting in better energy management and better fuel economy. Because the electronic wastegate properly controls the flow of exhaust gases, it helps reduce emissions and makes the engine run better overall. This is why they are an important part of modern turbo systems.

Integration of Turbocharging in Hybrid Vehicles:

As hybrid systems become more popular, manufacturers are looking for ways to add engine technology to hybrid systems. In hybrids, a turbocharger can be combined with an electric motor to make them more powerful without using more gasoline. When combined with regenerative braking and other energy-saving technologies, turbocharging can make hybrid vehicles more powerful and efficient.

Some automakers are even exploring the possibility of using electric turbochargers in hybrid vehicles since they don’t need to be connected to the exhaust system and can deliver power quickly. This integration allows hybrid vehicles to achieve the same performance levels as conventional turbocharged engines while still producing low emissions. This gives customers the best of both worlds. As hybrid technology continues to evolve, turbocharging could become an important component in maximizing speed and efficiency.

Electric Cars and the Future: Turbocharging

Turbochargers are typically attached to internal combustion engines, but some engineers are now exploring how they can be used in electric vehicles (EVs). Since electric vehicles don’t use combustion, they don’t need a turbocharger in the usual sense. However, turbocharging could be used to improve energy recovery or battery cooling systems, making the car more efficient overall.

Electric vehicles could potentially achieve greater range and higher speeds by using smaller electric turbines that can also recover energy during braking or improve battery pack cooling. While the technology is still being tested, it is clear that turbocharging can be used for more than just specific tasks. The future of turbocharging in electric vehicles (EVs) remains very exciting as engineers look for new ways to use the technology for purposes beyond combustion.

Conclusion:

Turbocharging technology has come a long way and is now an essential component of regular cars and hybrids. These new technologies, such as electric turbochargers and variable geometry designs, can make cars faster, more fuel efficient, and better able to control pollution. New materials are helping to extend the life of the turbocharger, and dual-stage turbocharging and wastegate technology are improving power distribution.

New developments in turbocharging technology could one-day power electric vehicles, marking the beginning of a new era for the technology. As the auto industry continues to focus on performance and efficiency, turbocharging will continue to be a key area of research, making vehicles more powerful, more efficient, and more environmentally friendly.

FAQs:

1. What is a turbocharger and how does it work?

A turbocharger increases the power of an engine by pushing more air into the combustion chamber. This burns more fuel and produces more power without making the engine heavier.

2. How is an electric turbocharger different from a regular turbocharger?

Electric turbochargers use an electric motor to drive a turbine instead of exhaust gases. This means they respond instantly and work better at lower speeds without the usual turbo lag.

3. What are the benefits of variable geometry turbochargers?

A variable geometry turbocharger (VGT) varies the flow of exhaust gases into the turbine to improve performance at all engine speeds and reduce turbo lag for a better driving experience.

4. Why is it important to use modern materials in turbotechnology?

Materials that can withstand high temperatures and pressure include titanium and ceramic. This helps the turbocharger last longer and work better without failure.

5. Can turbo technology help electric vehicles?

Although electric cars do not need a turbocharger to power their combustion, smaller electric turbines could help cool the battery or recycle energy, giving electric cars better range and speed.